> Business > Environment industry

| Activated carbon adsorption method |

Microorganism chemical adsorption method |

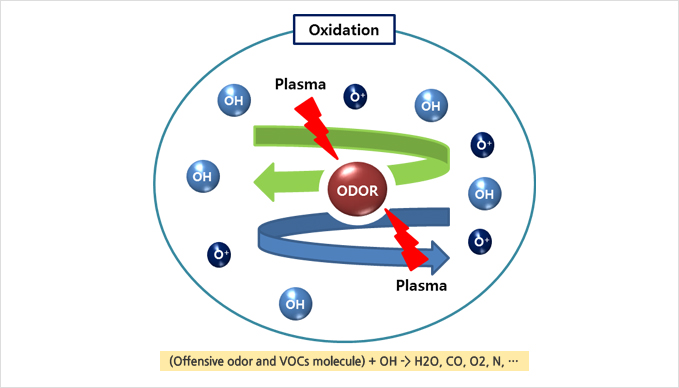

Plasma / ozone / photocatalyst oxidation method |

|

|---|---|---|---|

| Design standard |

Air volume : 50cm m(20℃) Contaminant: offensive odor (hydrogen sulfide, methyl mercaptan, ammonia, trimethylamine, formaldehyde) Offensive odor intensity : entrance (air dilution olfactory method over 1,000) exit (air dilution olfactory method 500 below) treatment efficiency : hydrogen sulfide over 90%, formaldehyde over 90%, ammonia over 90% |

||

| superficial velocity |

0.5m/sec | 0.3m/sec | 1~20m/sec |

| pressure loss |

150mmAq | 150~200mmAq | 100mmAq below |

| Main body size |

3,500w x 5,000L X 4,000H | D4,000w x 7,000h X 2sets | 2,500w x 2,500L X 2,300H |

| Installation area |

4,000mmW X 7,000mmL | 6,000mmW X 12,000mmL | 4,000mmW X 4,000mmL |

| Merit | Reasonable driving cost Reasonable installation investment cost Low concentration offensive odor with outstanding alkaline Acid + alkaline gas treatment |

Eco-friendly drug/ No secondary pollutants like water waste as catalyst is not used. beneficial to high concentration complex offensive odor gas Great efficiency |

Reasonable driving cost Reasonable installation investment cost Applicable to almost all the type of offensive odor. No secondary pollutants. The smallest installation space. No pressure loss Available to all the offensive odor |

| Demerits | Secondary pollutants due to activated carbon Water waste. Requiring corrosion - regular activated carbon exchange / regenerating facility. If 50~60% moisture existing in gas, trouble may be caused. |

Requiring microorganism initial stability periods. Large Installation site and expensive installation cost. Growth condition of the microorganism has to be secured. Requiring maintaining Gas, temperature, and humidity. It has to be careful in winter season because when error it takes long restoration time. |

Oh radical generation Exchange period 5,000 ~ 6,000 time |