Advanced Solutions

for the most efficient Filtration and smart Process management.Filter system

Liquid System

Providing TOTAL SERVICE of design, plan, and manufacturing.

Not only filtering system, it is applicable to use for industry process widely like Separation and Recovery.

Providing test service to select proper filter with various type of Pilot equipment.

- CATALYST RECOVERY SYSTEM

- PTA / CTA SYSTEM

- LITHIUM RECOVERY SYSTEM

- MAGNETIC FILTER SYSTEM

CATALYST RECOVERY SYSTEM (Catalyst Protect/Recovery system)

System special merit

- Dual structured metal filter

- System applicable to high temperature and high pressure

- Strong mechanical strength, superior heat/chemical durability

- Metal corrosion resisting filter system

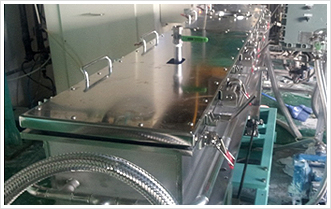

Installation picture

PTA / CTA SYSTEM

- CTA Recovery system - Mother liquid recovery system

System applied to acetate raw material process PTA (Purified Terephthalic Acid) it recoveries CTA equipped with acid-resistance Hastelloy with 24 hours continuous process, acid-resistance hastelloy. - PTA Recovery System - PTA recovery system

PSystem applied to all the stage of the industrial water waste treatment PTA (Purified terephthalic acid) Auto system to recovery PTA ultimately, around-the-clock process that metal Filter for high pressure is applied.

System special merit

- Improving 1 cycle filtration time and clean efficiency through volumetric filtration.

- Stable driving with dual filter of outstanding recovery

- Financial and efficient PTA / CTA recovery force function.

- Driving cost saving

- Shortening maintenance time

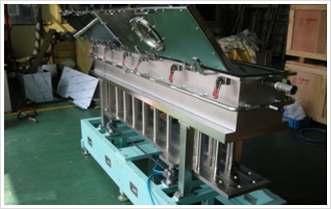

Installation picture

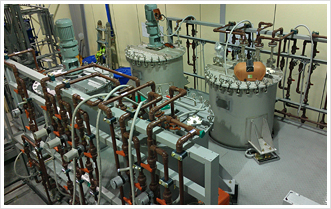

LITHIUM RECOVERY SYSTEM (Lithium recovery system)

System special merit

- dual structured metal filter

- Stable and effective driving for a long time

- Strong chemical durability

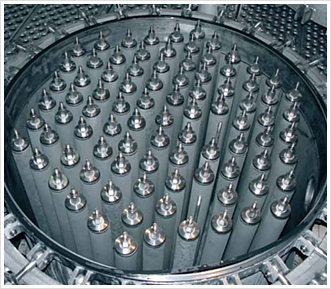

Installation picture

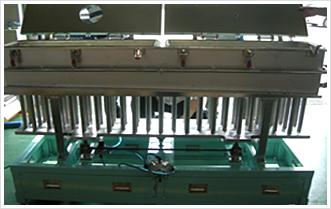

MAGNETIC FILTER SYSTEM (Magnetic filter system)

System special merit

- COMPACT Design

- Cost saving with simple cleaning process

- Stable and effective driving for a long time

- Shortening maintenance time

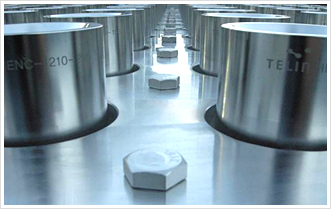

Installation picture

Candle Filter System

Candle Filter is a filter system suitable for dry cake recovery or filter regeneration, and Taerin provides a Total Candle Filter System including system design, engineering, construction, and commissioning.

The Candle Filter System typically consists of metal powder filters, metal fiber filters, sintered mesh filters, etc., arranged vertically or horizontally in pressure vessels.

Special merit of Our System

- Optimal design of filter regeneration system tailored to filter design

- High flow rates, high filtration precision, slow pressure build-up, long cycle periods

- High porosity and excellent permeability, minimal pressure loss

- Corrosion resistance, high temperature resistance, resistance to acids, alkalis, organic solvents, and drug corrosion, suitable for long-term use even at 400°C

- Automatic discharge of cake

- Excellent performance in filter regeneration (back washing or back pulsing).

Back Washing or Back Pulshing

Candle Filter

Gas System

Providing total service of the design, plan, manufacturing test.

Not only regular filtering system, it can be widely applied to many industry processes - separation,

recovery, Fluidizing, sliencing, sparging, degassing.

Providing various types of pilot and developing system to provide filter selection perfect for the processing

and the best processing condition.

- DUST REMOVAL SYSTEM FOR IGCC

- CVD OFF GAS SYSTEM

- DUST COLLECTOR SYSTEM

DUST REMOVAL SYSTEM FOR IGCC

System special merit

- Constant and stable driving for a long time

- High temperature / high pressure System

- Strong mechanical strength, and superior heat/chemical durability

- Metal corrosion resisting filter system and dust system for high temperature / high pressure

Installation picture

CVD OFF GAS SYSTEM

System special merit

- Constant and long-time driving

- Outstanding restoration when back flush with world patent dual structure filter

- Cost saving and efficient maintenance with long term driving

- High quality filtering efficiency due to surface filtration

- Strong mechanical strength, and superior heat/ chemical durability

- Metal corrosion resisting filter system and dust system for high temperature / high pressure

Installation picture

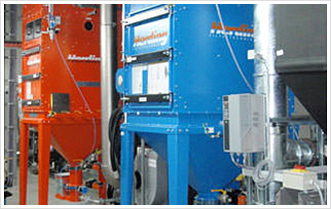

DUST COLLECTOR SYSTEM

The filter media consists of teflon coating on PE material.

System special merit

- 15-year of longest life span

- Maintenance cost saving due to superior filter durability

- Continuous air flow is guaranteed as the change of pressure differences is insignificant.

- High quality filtering efficiency due to surface filtration

- according to the characteristic of the dust, dust concentration of the refining Gas is 0.2mg/m below

- Cleaning, regenerating and modifying are possible

- Installable in either way raw gas or clean gas

- Both horizontal and vertical installation is available

- In this product, fiber is completely excluded.

- Fiber suitable for dust

- Antistatic function

- Securing harmlessness approvals by FDA

Installation picture

Cleaning System

Providing total service - design, plan, construction, and test drive.

This system is optimized to contribute for cost saving and process efficiency by regenerating Filter used for filtering system to perform successfully like new product.

Special merit of Our System

- Specialized plan for the characteristic of the filter

- Movement optimization with compact plan

- Chemical treatment, heat treatment, mechanical treatment complex composition

- Before & after cleaning quality check

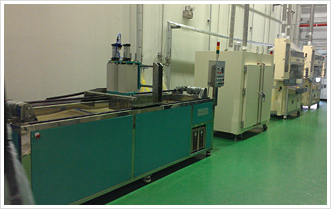

Installation picture